Physics Classroom Equipment

At the end of my prep/freshman year at Phillips Exeter Academy, the physics department lab head heard of my design and manufacturing work through the PEA design lab leader.

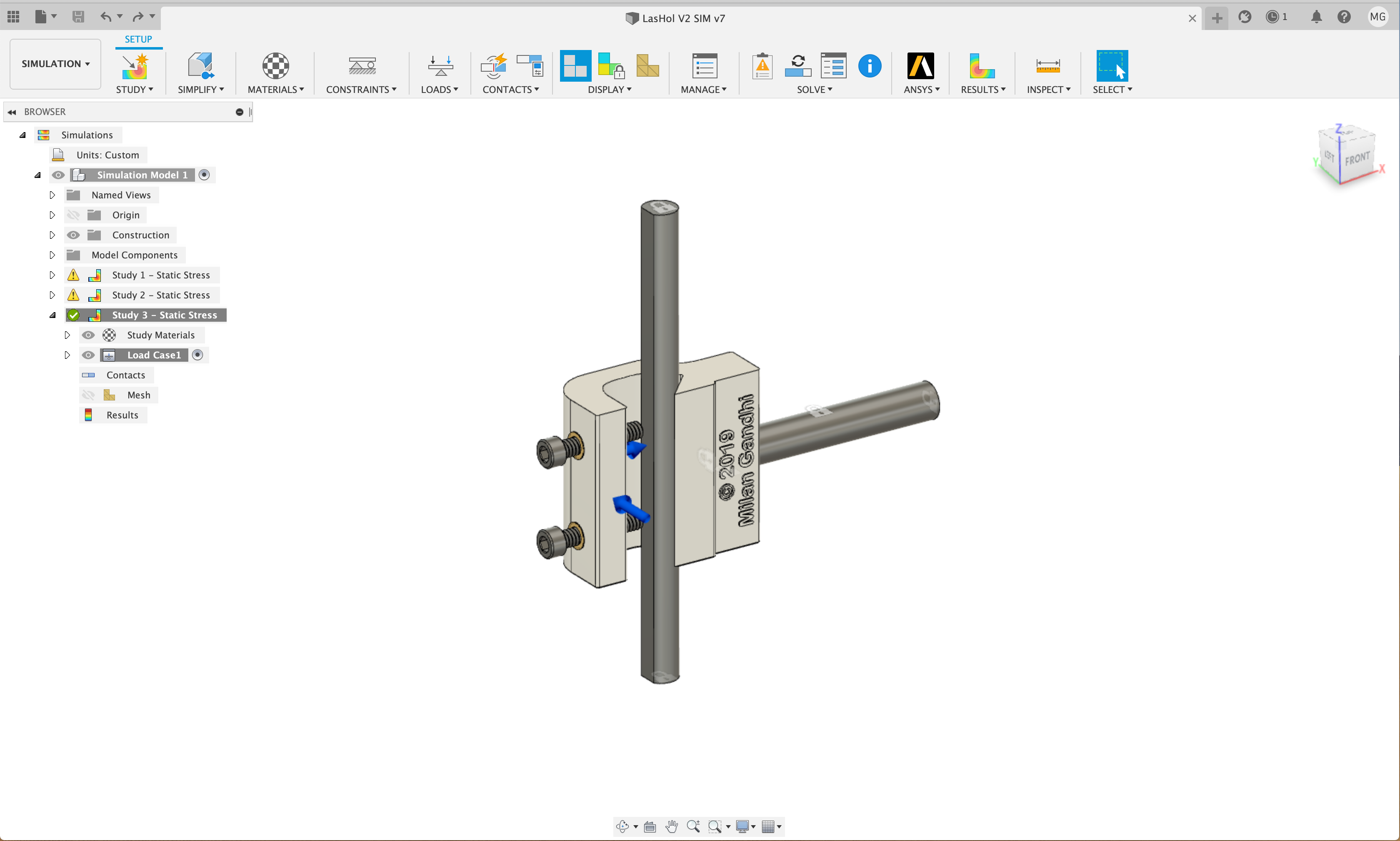

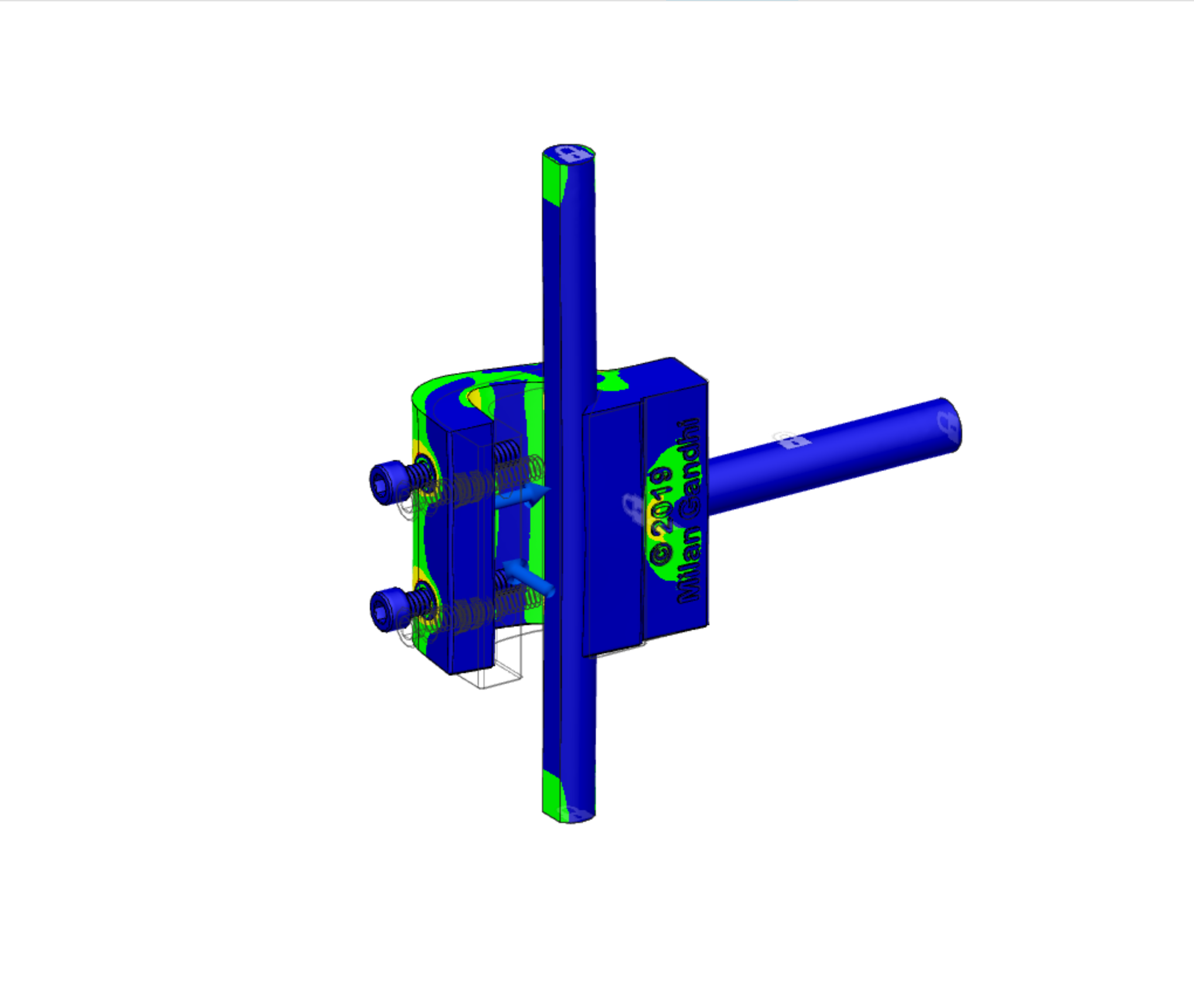

The physics lab head then approached me, asking if I could re-create a certain laser clamp holder used in the physics classrooms. I worked with her to identify an equipment requirement including specifications for the given laser clamp holder jig. That specific part was on short supply, and it was costly to replace/implement with traditional parts.

Instead of purchasing the costly parts, I reverse engineered the existing part using scanning and design techniques, and then assembled the final model in CAD software. I then worked with the physics lab head to order the hardware necessary to supplement the additively manufactured primary component(s). From the CAD model created, I additively manufactured the primary holder component using in-house machine(s), and arrived at the final iteration after several rounds of iteration. Then, using the aggregated hardware, I assembled the screws, inserts, and other hardware, as well as the additively manufactured primary components, to produce the final working parts. I then shipped the final working parts back to school, and the Physics laboratory head implemented the newly created parts into the lab.

Overall, the project was a win-win scenario for both parties, and by fabrication the parts through me, the lab head saved the department 90% of their budget allotment for replacing those parts.